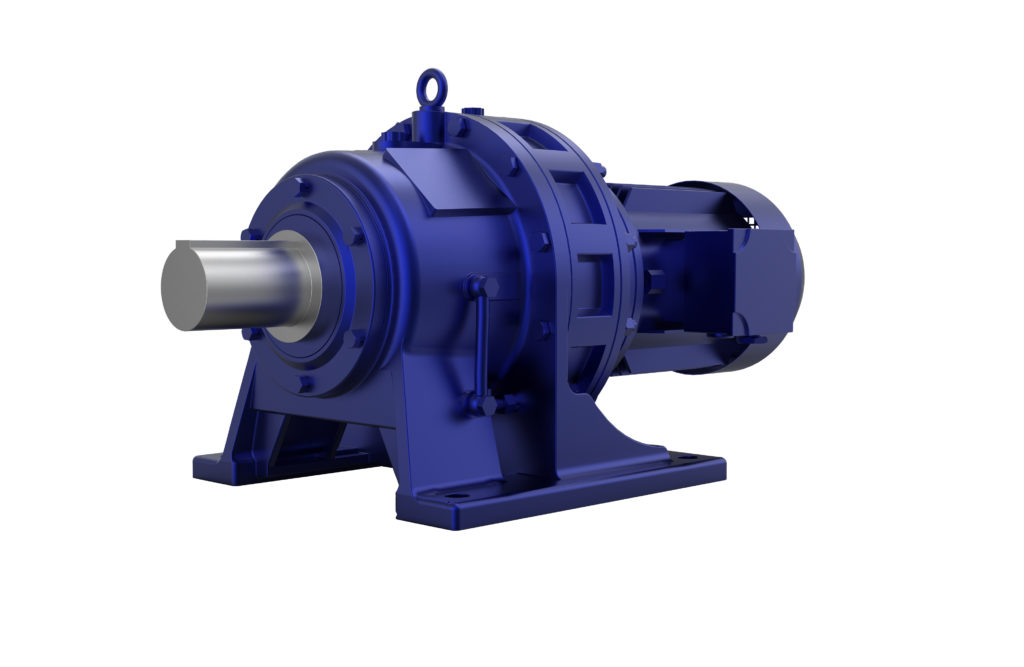

Our B Series Cycloid reducer is an ideal solution for Small & Medium Size manufacturers, since it can achieve relatively high gear ratios in compact sizes and provide cost-saving solutions.

Due to the compact, yet simple design, our B Series can substitute with helical in-line model while achieving cost saving, cutting the costs of your project. Moreover, with advanced production technologies including heat-treating and final gear tooth machining and premium component such as grey cast iron and SKF bearing, our cycloid model can achieve great operation capacity in terms of overloading capacity, noise level, transmission efficiency and structure strengthen.

Due to the compact, yet simple design, our B Series can substitute with helical in-line model while achieving cost saving, cutting the costs of your project. Moreover, with advanced production technologies including heat-treating and final gear tooth machining and premium component such as grey cast iron and SKF bearing, our cycloid model can achieve great operation capacity in terms of overloading capacity, noise level, transmission efficiency and structure strengthen.

Please check out our Cycloid Video for our production processes

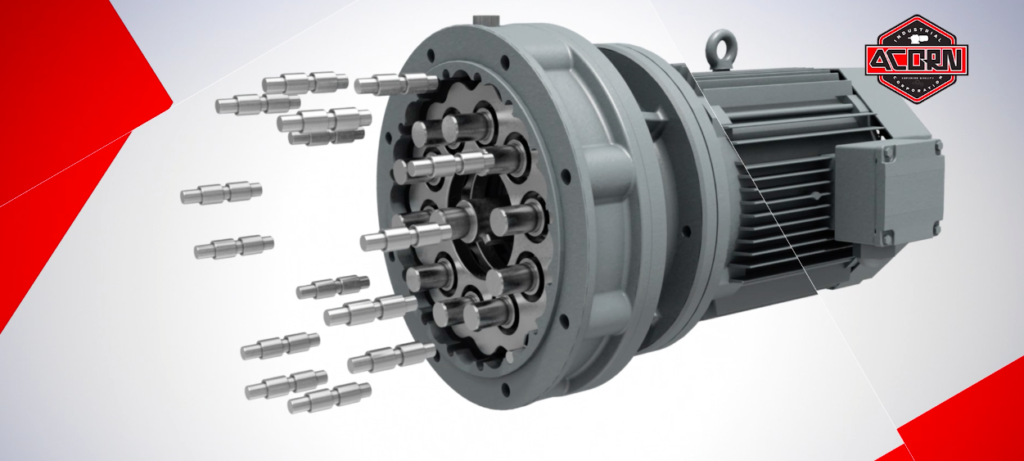

Mechanism

The input shaft is mounted eccentrically to a cylindrical roller bearing, making the cycloid disc to move in a circle. The cycloid disc will independently rotate around the bearing as it is pushed against the ring gear. The number of pins on the ring gear is larger than the number of pins on the cycloid disc. This causes the cycloid disc to rotate around the bearing faster than the input shaft is moving it around, giving an overall rotation in the direction opposing the rotation of the input shaft.

The cycloid disc has holes that are slightly larger than the output roller pins that go inside them. The output pins will move around in the holes to achieve steady rotation of the output shaft from the wobbling movement of the cycloid disc.

Check out this video for 3D decomposition

Technical Specifications

Our B Series can achieve: single stage efficiency approaches around 93% and double stage approaches around 86%. Single stage reductions are available up to 119:1 and double stage up to 7569:1. Torque ranges from 30Nm – 29,400Nm.