Achieve EXCELLENCE, Start From The Gear

Gear is the soul of reducer. Acorn Industrial Corporation fully understands this concept, and so put much attention on making high quality gears. We have invested heavily in gear manufacturing and processing to ensure all the gears comply with international industrial standards.

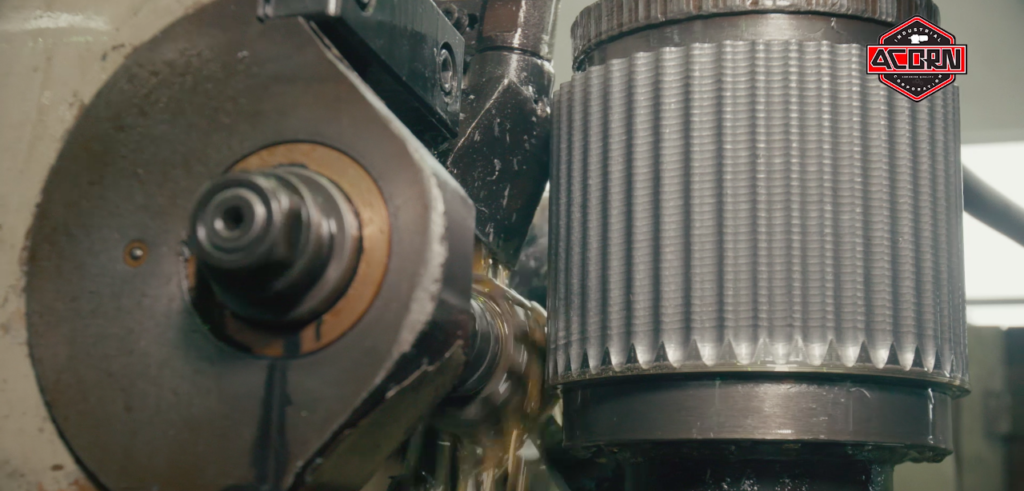

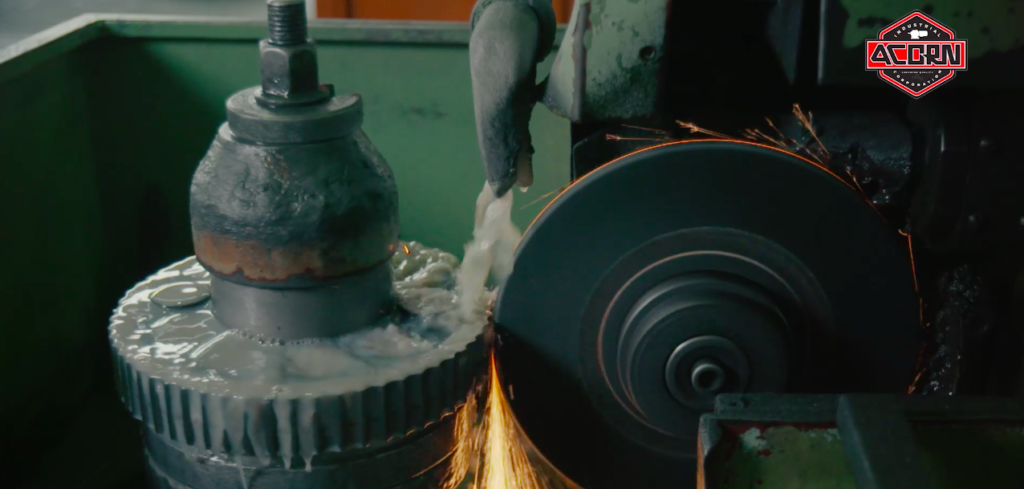

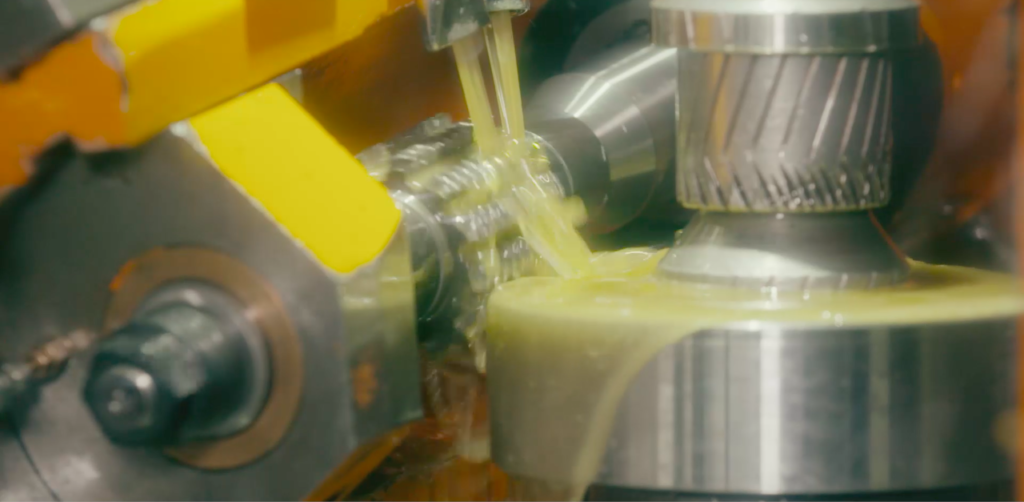

The heart of our factory is the machinery center. It is filled with high-tech and high-end brand gear processing machines, such as GLEASON and NILES from Germany and Okuma from Japan. These machines perform various processes, such as casting, forging, extrusion, powder metallurgy, and blanking and final inspection and testing in order to achieve the final dimensions, shape and surface required.

With our high-tech production processes, all our gears comply with international industrial standard, such as America Gear Manufacture Association standard 12-14 to ensure high accuracy and high durability.

Achieve EXCELLENCE – Keep Exploring, Bringing humankind to the space

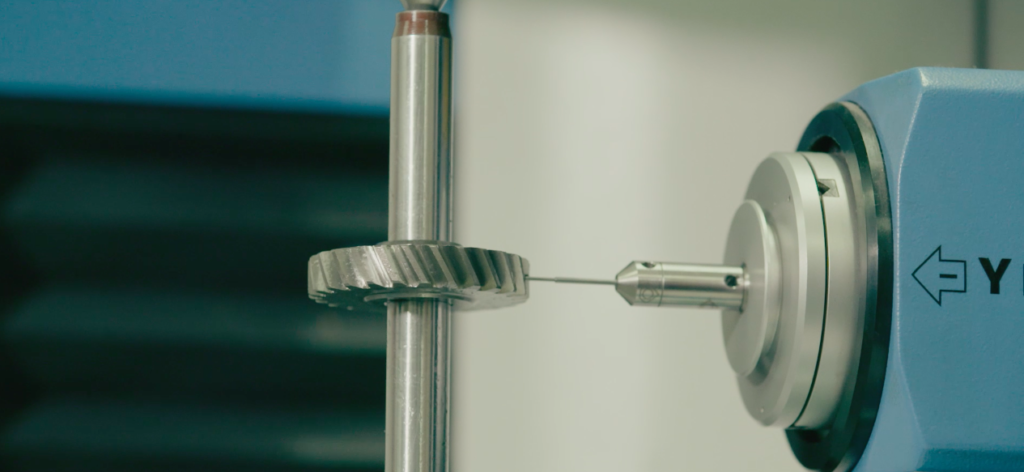

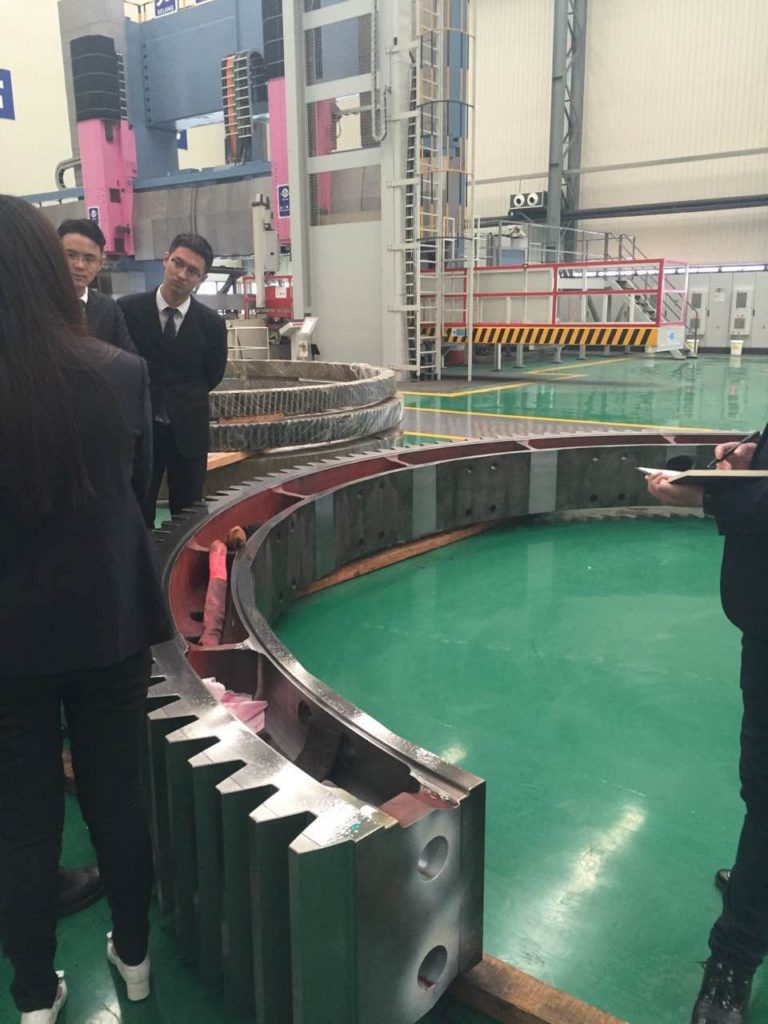

ACORN strives to achieve more. The aerospace industry is one of the sectors, which demand high quality gears with extremely level of accuracy and performance standard. As we excel in gear manufacturing and processing, we have been a major supplier for the Chinese aerospace industry, designing and producing precision gears as well as other components used in launch of rockets. For example, below is a unit gear of 8 diameters used to move and direct rockets into launching position.

ACORN strives to achieve more. The aerospace industry is one of the sectors, which demand high quality gears with extremely level of accuracy and performance standard. As we excel in gear manufacturing and processing, we have been a major supplier for the Chinese aerospace industry, designing and producing precision gears as well as other components used in launch of rockets. For example, below is a unit gear of 8 diameters used to move and direct rockets into launching position.

To be able to manage a rocket that costs billions of dollars, our designers cannot tolerate any degree of discrepancy. By bringing the same philosophy to gearbox production, we are confident that our products can achieve life-long services.